It is generally recognized that CH2M HILL’s bootstrap project was a Water Treatment Plant, designed and built during the late 1960s and the early 1970s. Its design and completion were the result of a number of forces combining, like the rare alignment of the planets, into a series of events which culminated in the creation of a modern-day wonder for that time period.

The Lake Tahoe Story

John Muir in 1873 called Lake Tahoe the “queen of lakes.” In a letter to a friend, he wrote, “The soul of Indian summer is brooding this blue water, and it enters one’s being as nothing else does. Tahoe is surely not one but many. As I curve around its heads and bays and look far out on its level sky fairly tinted and fading in pensive air, I am reminded of all the mountain lakes I ever knew, as if this were a kind of water heaven to which they all had come.”

Lake Tahoe is one of the clearest lakes in the world. At 22 miles long and 12 miles wide, the alpine lake has 75 miles of spectacular shoreline. And with a depth of 1,645 feet, it is one of the deepest lakes in the world. Nestled in the Sierra Nevada and Carson mountains, Lake Tahoe is an economic gem for the local community and an icon of the nation’s scenic treasures. It is a haven for tourists, skiers, casino gamblers, and outdoor enthusiasts.

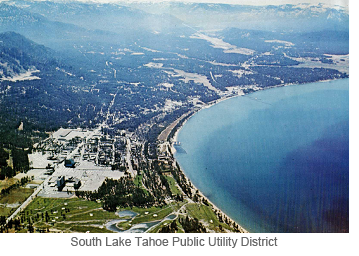

The rapid growth of the area is reflected in the development, expansion, and struggles of the South Tahoe Public Utility District, the area’s largest provider of wastewater treatment. In the early 1950s, the District’s area of responsibility covered a mere 140 acres. It used two redwood septic tanks and disposed of the effluent by spraying it on open land. But as more and more people were attracted to the area, the District’s responsibilities rapidly expanded; and it was forced to scramble to meet the needs of the community. In 1960, the District built a 2-million-gallon-per-day (mgd) activated-sludge-treatment plant. The District had no choice, albeit ill-fated, but to continue its practice of land disposal. This was due to state regulations that barred the discharge of conventionally treated effluent into the lake or the streams of the area.

Clair A. Hill & Associates (CAHA) worked continuously for the district for nearly a decade and, along with CH2M, helped keep Lake Tahoe a crystal-clear alpine lake and a national treasure.

At issue was the phosphorus- and nitrogen-rich effluent that would feed algae and cloud the pure, clear waters of Lake Tahoe. As the amount of wastewater being treated increased, to keep up with the rush of newcomers, troubles continued for the District. Time and again, an overabundance of effluent flowed off already-saturated land, only to wash into the lake. It was an ongoing environmental nightmare that haunted the District’s beleaguered board of directors, who were under pressure from a plethora of government entities that included two states, various federal agencies, and five counties—a combined total of more than 65 government agencies—as well as the community at large.

In 1961, district director Earl Pankost called CAHA, which had recently designed a sewer collection system for South Lake Tahoe. Pankost and the board were looking to the firm to come up with options for a permanent, environmentally safe wastewater solution. With Harlan Moyer leading the effort, two alternatives beyond status quo were brought to the board: (1) develop an advanced method of wastewater treatment that might allow effluent to be disposed of in the lake basin or (2) find feasible routes for removing effluent (treated to near-drinking-water quality) from the basin and negotiate an agreement that would allow disposal of effluent to a watershed outside the basin.

Either approach would require time for planning, community hearings, regulatory approval, financing, and construction. An interim plan also would be needed to expand land disposal efforts until a permanent plan could be developed and facilities built. Moreover, either alternative would require a complex system that would take raw sewage in and produce odorless, clear, near drinking-quality water—a process that had not yet been developed.

The board of directors again turned to CAHA to help sort out the best alternative. The firm had the wherewithal to do the design and construction management for virtually any plan the board would approve, but needed to call on colleagues at CH2M, who were treading new waters in sanitation technology.

“I called Ralph (Roderick) and described our problem,” Moyer said. “He said ‘Heck, I think we can develop a third-stage treatment system to remove solids, phosphorous, and nitrogen, and then we can discharge the effluent anywhere, including into Lake Tahoe.'”

CH2M had already developed a tertiary treatment that Roderick believed, if combined with other industry technology, could be the end-all cure for South Tahoe. Microfloc, as it is known today, is a rapid multimedia filtration system that was born out of the federal government’s Hanford site in Washington, which was home to the world’s first full-scale nuclear reactor. Walt Conley and Ray Pitman had developed PIT-CON, the predecessor of Microfloc. PIT-CON was a filtering process using sand and coal to treat water from the Columbia River that cooled reactors, which manufactured plutonium for the nation’s nuclear arsenal.

Archie Rice, CH2M, had recently hired Conley to conduct research and development for CH2M subsidiary Microfloc Corporation. Conley and other staffers worked to improve the filtration process by adding other granular media such as garnet and graphite-sand, so the process could be used for municipal water treatment. All this was being done in a rented garage belonging to a local Corvallis radio station. They developed a portable plant called the Water Boy. It was capable of drawing in what The Oregonian newspaper described as “grossly contaminated water” and producing potable water. Water Boy, which can treat as much as 150,000 gallons a day, continues to be used worldwide.

“The only way we could make this water any better,” Rice told a newspaper reporter while demonstrating the technology, “would be to add bourbon to it.”

The treatment process caught Roderick’s eye and the attention of others at CH2M who were working in the environmental engineering discipline. Russell Culp helped lead the effort to further enhance the technology for use in sewage treatment by revising the filter backwash system. The backwash system was vital to the success of the technology, if it were to be converted for treatment of wastewater.

Moyer and Roderick met with the South Tahoe District’s board to discuss this new method of treatment.

Ralph, in his down-home manner, described the work done at the Hanford nuclear reservation and how his colleagues had developed a successful filtering system and how phosphorous could be removed by a coagulation process using alum,” Moyer said. “He also discussed how activated carbon could be used to remove color and dissolved organics from the effluent.

“The board became more enthusiastic the longer Roderick spoke.”

And after hours of discussion, board members asked the two engineers what it would take to implement an advanced wastewater treatment system. Their response was that funding would be needed for a pilot plant, bringing together conventional treatment, the Microfloc processes, alum treatment (eventually replaced with lime), carbon columns, and carbon-regeneration equipment.

Board members questioned what this pilot plant would cost, and after a brief one-on-one discussion, the engineers said it would require roughly $30,000 to launch. Roderick and Moyer were confident enough in the technology and pending success of the pilot that they offered $15,000 as seed money. Before the meeting wrapped up, the board—still reeling from public and regulatory scrutiny and criticism, as well as election recall efforts—took an unprecedented step in giving the engineers the green light to proceed. And although the pilot plant would fit on a small trailer and only treat a few gallons a minute, the board’s decision was a bold, pioneering move.

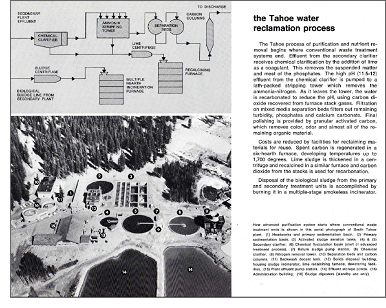

Once the pilot was underway, additional funding to support the project came from grants provided by the U.S. Public Health Service. The pilot was successfully completed in 1963, which then led to the design and construction of the world’s first full-scale advanced wastewater treatment facility, capable of processing 2.5 mgd. The unique design of the plant also included a system for recovering and reusing the alum coagulant. This alum-recovery system, based on original research by Dr. Gerald Rohlich of the University of Wisconsin, offered a potential way to minimize coagulant costs. And, more importantly, the system would solve the problem of disposing of an otherwise voluminous and slimy sludge containing the particulate matter removed from the wastewater. The plant design led by Culp and Gene Suhr proved to be reasonably successful. The alum-recovery system, however, did not perform in practice as well as it had in laboratory testing and was not constructed in full scale. This meant that an interim means of disposing of the difficult-to-process alum sludge would be required, unless an alternate phosphorus removal system could be employed. Even before completion, though, due to skyrocketing growth of the Tahoe area, the facility was overloaded. Again, the South Tahoe District scrambled, and again it called on the collaborative efforts of Clair A. Hill & Associates and CH2M. By the mid-1960s, the advanced wastewater treatment facility had been expanded threefold, with funding provided by the District, the State of California, and the federal government.

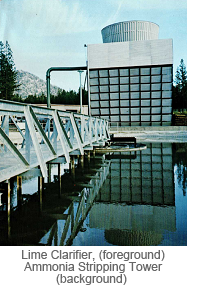

Refinements to the treatment process were introduced as a part of the expansion of the facility. Suhr proposed the use of lime as a coagulant, which proved not only to remove phosphorus better, but also ameliorated the problems attendant to alum sludge disposal. An added benefit of lime coagulation was the ability to readily recover and reuse the lime by heating the sludge in a furnace to convert the lime sludge into calcium oxide or quicklime. The use of lime also made it possible to remove nitrogen from the wastewater; this could be done by using a stripping process that resembles conventional cooling towers. The lime served to elevate the pH of the wastewater so that most of the nitrogen present was in the form of ammonia, thus enabling stripping.

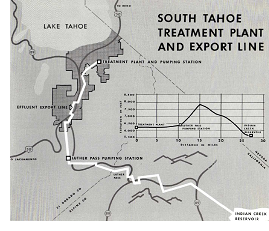

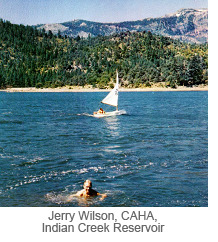

A stripping tower was completed in 1968. It removed 95 percent of the toxic ammonia. But despite the near drinking water quality of the effluent, stringent regulations still would not allow the output of the facility to flow into Lake Tahoe. The District continued its land disposal of effluent, leasing additional land, year after year. State and federal agencies were urging the District to export the effluent outside the Tahoe basin. After considering three export options, the final choice was to build a 27-mile pipeline over Luther Pass to Diamond Valley. This required a pumping station to move the water more than 1,440 feet up over the pass before emptying into the Indian Creek Reservoir. The dam and reservoir were built to receive the effluent and are a key and final component of the South Tahoe project. The effluent was declared pure enough that the reservoir could be used for all water contact recreational activities, and it is also a source of irrigation for local farms. Read More… (PDF)

From 1951 through 1968, more than $28 million were spent on the project. Culp went on to become the District’s general manager in 1968. Moyer was the project manager from 1960 through 1968 and also served as the District’s consulting general manager for two separate stints, in 1961 and from 1966 to 1968.

At the completion of various stages of the near decade-long project, local and state politicians and other interested parties, learning of this never-used-before technology, flocked to the tertiary treatment plant. They included Oregon Governor Tom McCall; [pictured here] California Congressman Harold T. (Bizz) Johnson, who was instrumental in bringing federal funding to the project, as well as the attention of the nation’s lawmakers; and California Governor Ronald Reagan, who narrated an educational film on the Lake Tahoe treatment facility. [Click here to see this film]

“I consider this to be an outstanding example of how to provide for both today’s use and enjoyment of the lake and to ensure that it remains an unimpaired natural resource to be enjoyed by our children and their children’s children. The technology now being employed at Lake Tahoe could well become an important weapon in the fight to clean up America’s waters,” Reagan said.

“Our best example of advanced wastewater treatment is that practiced at Lake Tahoe. . . .The Tahoe plant has clearly demonstrated that there is no need for wastewater, or the by-products of its treatment, to pollute the environment,” said William D. Ruckelshaus, the first administrator for the Environmental Protection Agency.

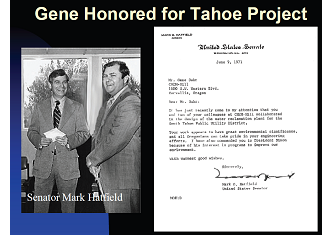

The treatment facility itself became a destination point for academics, wastewater engineers, officials from regulatory agencies worldwide, and even the general public. It was featured in a variety of publications, including The New York Times, The Denver Post, Reader’s Digest, and the Los Angeles Times. In April 1972, Roderick, Moyer, and Suhr were honored by a presidential citation, personally delivered by then Oregon Senator Mark Hatfield, for their pioneering work on the Tahoe project.

As word spread about tertiary treatment, gaining the attention of wastewater districts nationwide, a wellspring of client interest developed for the two engineering firms.

In a December 1969 letter from Ralph Roderick to Harlan Moyer concerning the City and County of Denver’s short list of engineering consultants to build a pilot wastewater reclamation facility, Roderick stated, in closing, “. . . we are able to run with the big boys. Now we have to move on and lead them.”

And lead they did. The Lake Tahoe tertiary treatment plant—and the $15,000 investment from CAHA and CH2M—has had a tremendous, positive impact on the health of the planet and the lives of people worldwide as tertiary treatment became widely used. Moreover, it brought together two fairly small engineering firms with unique values and common interests in exceeding client expectations, yielding one of the world’s finest and largest engineering organizations.

The merged CH2M HILL went on to tackle projects such as the massive Upper Occoquan Sewage Authority program in northern Virginia; the design of a planned facility in Montgomery County, Maryland; the Tahoe-Truckee Advanced Waste Treatment Plant; and the Denver Water Board Successive Reuse Project.

To put it into perspective, Archie Rice said, “All of a sudden, we didn’t have to come up with an explanation as to where Corvallis was.”

Many publications presented articles about the Lake Tahoe Story. In the general (non technical) public press, the most note worthy article was the Readers Digest Article (PDF) is attached to this e-mail.

The Tahoe Story Films

December 15, 2011

In 2011, two 16-mm films describing the Advanced Wastewater Treatment (AWT) Plant at the South Lake Tahoe Public Utility District (STPUD) at South Lake Tahoe, CA, were found in the CH2M HILL archives. As described below, both films were produced in the early part of the 1970 decade for different reasons. These two films have just been converted, unedited, to a DVD format.

For those using an Apple computer, there is a MAC (Apple) version on the DVD that seems to work.

“DVD Film” Titled “South Lake Tahoe – Pure Water from Wastewater”

In the early 1960s, pilot plant studies were conducted that first led to a 2.5 million-gallon-per-day (mgd) Advanced Wastewater Treatment (AWT) Plant and then ultimately to a 7.5-mgd facility that became operational in 1968. This AWT facility, at South Lake Tahoe, was the first of its kind, at this scale, worldwide. The project was funded in part by the U.S. Federal Government to demonstrate how the ultimate wastewater reclamation technologies of that day could reclaim wastewater.

This first 16-mm film about the “South Lake Tahoe Process,” produced in 1969/1970 and introduced by the then Governor of California, Ronald Regan, and the later President of the United States, was intended to present these AWT “demonstration” technologies to the world. The film was shown to thousands of visitors to the STPUD facility and to worldwide conferences. It may be of interest to note that the film was shown aboard the first TWA transatlantic Boeing 747 flight in conjunction with a trade Mission sponsored by the U.S. Department of Commerce. The film’s producers, the STPUD, the design consulting firms of CH2M and Clair Hill and Associates, and suppliers chose not to copyright the film and to provide complementary copies of the film to the STPUD, the Federal Government, and perhaps others.

“DVD Film” Titled “Wastewater – Reject or Resource, South Lake Tahoe Pure Water from Wastewater”

This second film, made in about 1974, was produced to update the STPUD Advanced Wastewater Treatment (AWT) process technology and to reflect regulatory and public interests of the time. This 16-mm film indicates a copyright by STPUD, all rights reserved, and by CH2M HILL.

This film’s added process technology update shows the addition of high-pressure spray nozzles and break-point chlorination to further strip ammonia nitrogen at high pH following the Ammonia Stripping Tower.

At the same time, regulatory and public interests were focusing on population growth issues at South Lake Tahoe, the ability of this AWT plant to continuously meet water quality standards that were higher than many drinking water standards, operating costs, and the reuse of the reclaimed water for fishery and irrigation uses outside the Lake Tahoe basin. In Alpine County, CA, the AWT discharge reservoir, Indian Creek Reservoir, had been located at that time to meet California State Law preventing reclaimed wastewater discharge to Lake Tahoe while still benefiting downstream users.