Residuals by Rep or Don’t get me Started

Thoughts from the first years of my 30 years with CH2M HILL are a joy, for the most part. Of course, many of my memories of the 50s and 60s are of people who are gone. Only a relative few will remember the setting for many of my memories, like the old Corvallis office on Western Blvd. Isn’t it great that, if we can remember anything, it tends to be the pleasant happenings?

Cornell, Howland, Hayes & Merryfield hired me in 1957 (Employee # 44). This was about 10 years after the “Firm” was started. The Firm had completed many water and sewage projects (later to be called wastewater projects). A majority were for Willamette Valley cities. These successful projects and the vision of the partners paved the way for the growth that resulted in a need to hire more people- – -like me. Hurray!

Getting Started

I graduated from OSU on a Monday, reported for work (with my K&E Log Duplex Decitrig slide rule) on Tuesday, and our first child arrived on Wednesday. A couple weeks later, I became a resident inspector on a significant water project: the water supply system for the new GP pulp mill at Toledo, Oregon.

The Initial Focus of Cornell, Howland, Hayes & Merryfield

The following are nearly forgotten publications of the Oregon State Engineering Experiment Station. I can’t recommend all these for detailed study. Note the focus of Fred’s work in the mid-1930s to the end of WWII when the firm was started.

Industrial and Domestic Wastes of the Willamette Valley, by G. W. Gleeson and F. Merryfield. 1936.

A Preliminary Survey of Industrial Pollution of Oregon Streams, by Fred Merryfield, chairman, Subcommittee on present stream conditions. June 1937.

1945 Progress Report on Pollution of Oregon Streams, by Fred Merryfield and W.G. Wilmot. 1945.

The Fishes of the Willamette River System in Relation to Pollution, by R.E. Dimick and Fred Merryfield. 1945.

Industrial and City Wastes, by Fred Merryfield, W.B. Bollen, [and] F.G. Kachelhoffer. 1947.

Fred was instrumental in measuring and documenting early water quality problems in Oregon.

One Will Do

Somehow Archie Rice had secured a job for Alpenrose Dairy at its Portland complex, which included a dairy (with cow poop), a milk bottling plant, and an ice cream plant. I was to help Archie design a treatment plant for a waste of characteristics to be determined. The dairy was to stop discharging untreated waste to an intermittent stream. The client had selected the treatment technology to be designed.

The process was to use the theories of a professor Nandor Porges, a microbiologist, at the University of Wisconsin. He had developed a biological process for dairy waste that produced no sludge. All that was available was a technical paper he had written. Not to worry, Nandor was coming to Portland and would explain the details of the process to us. Unfortunately, Nandor died the week before our scheduled meeting.

From the Journal of Dairy Science

NANDOR PORGES, 57, a microbiologist with the USDA since 1937, died suddenly April 1, 1959, at the home of his mother in New Brunswick, N.J. He had attended the funeral of his father the day before.

We proceeded to design a treatment unit, one of a kind, and it worked with only minor problems. Well – – – at least it satisfied the client. I’m not sure what happened to the sludge. I don’t know who sampled and tested the effluent.

We only designed one.

Elevating Sewage (Wastewater)

For 2 years of my many years of schooling, I worked as an operator at the Corvallis STP where I had been “submerged” in a CH2M-designed plant that included a lift station that used pumps driven with variable-speed, electrical motors.

I gradually realized that the pump control system that made this possible was invented by people at CH2M. The Flomatcher made it possible to reduce pump station size and overcome numerous operation problems (best left undescribed).

Flomatcher was a key to securing many projects for the firm. It was spun-off to become a manufacturing business.

Poor Jim or Personnel 101

It became obvious that one of our new hires, an engineer, was carrying water conservation too far at the expense of indoor air pollution. In other words, he was not in the habit of frequently bathing.

In those days, Jim Howland headed the office (I think). At least he was somehow selected to discuss the problem with the fellow.

Whatever Jim said worked.

I recall, with considerable clarity, that on a couple of occasions Jim invited me to his office to inquire as to my actions:

1.) Joe Worth and I had taken his Buick on a fishing trip. The car had a mechanical failure near Bend. Bend is 130 miles from CVO. Not to worry, we just rented a car to tow Joe’s car home. We used the Firm’s name to get the best rental rate (unfortunately). In the fine print of the rental contract, towing is excluded as a permitted use. The rental company manager had called Jim and expressed his displeasure and proposed – – – – well – – – you don’t have time for the details. Jim suggested how our problem might be solved. It had merit.

2.) One the second occasion, I had blurted out in a meeting with a client and Jim that “the design we had previously provided “won’t work.” Jim later (in his office) suggested several alternative ways I might have stated the problem. They did have merit.

3.) Hardly worth mentioning- – – –

Bless you and thank you Jim; you are a gentleman.

A Big Job

About 1955, Georgia Pacific (GP) had selected the Firm to help GP develop a water supply and a disposal system for the mill waste for their new pulp mill at Toledo, Oregon. The mill celebrated its 50th anniversary this year. When I joined the Firm, the jobs had been designed and bid and were under construction. I was to be a member of the field team that numbered about six people. Jim Poirot was the project manager.

The project included a pump station with fish screen on the Siletz River, 1.5 miles of 27-inch concrete cylinder pressure pipe that carried the water to the top of the ridge between the drainage basins of the Siletz River and the Yaquina River, an earth-fill storage dam on Olalla Creek, a salt water barrier and pump station at Toledo, 0.4 mile of 30-inch pipe to the mill, a waste pump station, a suspension bridge, and 8 miles of 12-inch steel waste line to the ocean at Newport.

Note that I cleverly mentioned concrete cylinder pipe in the prior paragraph. Those of you familiar with concrete cylinder may recall that the pipe came in +/- 33-foot lengths and the interior of the joints must be filled. In 1957, they were filled by hand with concrete grout (in accordance with the workmanship section of our documents). This meant that the inspector had to crawl into this very dark hole, sometimes a couple hundred feet and back out the same way. Access manholes were not essential nor provided. One of my unrecognized talents of my youth was the ability to turn around in a 28-inch pipe.

Ooh- – – now it pains me to even think about such a contortion.

CH2M HILL has served GP at this site for over 50 years. Roger Lindquist recently told me that we still inspect the dam each year. The firm has had numerous projects for the mill since 1958 including at least two to extend and modify the Newport ocean outfall. This means that this mill has been a client every year for 50+ years!

This was/is a significant water project for CH2M HILL and Oregon.

One Potato, Two Potato – – – – 500,000 Pounds per Day

In 1960, I was near the end of my second residency: the Eugene, Oregon, wastewater plant expansion. Earl Reynolds, BOI manager, asked me to get to Idaho ASAP. He had a job for a potato processor in Idaho Falls. I had never seen a potato processing plant.

How do you get to Idaho Falls? Oh, you fly on a West Coast Airlines DC 3 (that is an unpressurized plane from the mid-1930s). It makes a few stops between CVO and Idaho Falls including Portland, Pendleton, Baker City, Ontario, Boise, Sun Valley, Burley, Pocatello, and Twin Falls. The flight ruins a full day.

The job was for Rogers Brothers and was the beginning of a long friendship with the developer of potato flakes and several other potato products.

This job gave us an entry into a major client group. The jobs were interesting and profitable. They resulted in major water quality improvements in several states and helped the industry expand.

International Work

The first effort to secure an international job, I recall, was in the mid-1960s when Ralph Roderick (head of wastewater) returned from Venezuela with the distinct impression that we would soon be selected by the Venezuelan government to study and design a sewage collection and treatment system for their capital city, Caracas. I was asked to consider going to Venezuela for a couple (more likely 10) years. “OK.” Dot and I started packing a few things and bought one of those books on learning Spanish quickly and easily.

We read about Venezuela and Caracas. This resulted in more than a few misgivings. Wow, it will be a tough environment and a tough job! And, I was green as a slab of newly poured concrete.

We didn’t get the job. Oh darn! Whew – – – that was close. Ralph may not have understood how business was done in Venezuela? By now, we must have unpacked the boxes.

Work, Work, Work

Well – – – not all the time. There were activities such as the picnics, fishing trips, pre-Christmas office parties (with liquor), Christmas parties, flying club (with airplane), annual meetings, softball teams, seminars, and (my favorite) conferences.

I soon learned that small conferences meet in such interesting places as: Sun Valley, Idaho (the pool seemed much smaller than represented in the movie “Sun Valley Serenade” staring skater Sonja Henie”); Pacific Grove, CA; Santa Barbara, CA; Big Rapids, MI ( no, not Grand Rapids); Jackson Hole, WY; Kelowna, B.C., Canada; and College Station, TX (OK – – not a winner- – – but I did see my first wild armadillo).

And then there were continuing education efforts. Sid Lasswell encouraged me to attend a 3-day, mid-summer, bio-treatment seminar at Manhattan College, NY. Sid was my boss at the time. Registration included onsite accommodations. We were housed in what was nicknamed the monk-house. Monks don’t get air conditioned facilities and, of course, liquor was not allowed. Sid never attended.

The Idea Book

I don’t know who started the idea book. People in the firm are always generating interesting and sometimes usable product ideas. In an effort to save these people were encouraged to record them in The Idea Book.

Each idea recorded has a story. The last idea I remember was a novel system designed by Roy Taylor/BOI for overcoming the formation of frazel ice (Google it) on river intake bar screens.

Coffee or Pulp Liquor

In the 50s and 60s, the office boiler room also accommodated our coffee breaks. We each had our own ceramic cups that hung on a wall peg. I still have my cup- – – somewhere. This was not an environmental consideration. This may predate paper and foam-plastic cups? Oh, I think we also donated to buy the coffee (honor system). The boiler/coffee room was our social center.

Many of us have warm and fuzzy memories of Austin Evanson. Austin was English and a mechanical engineer with diverse interests and great talent. Austin had even practiced engineering in India. Austin smoked a well-aged pipe when he was thinking. He thought a lot- – -eh.

Cornell, Howland, Hayes & Merryfield, Inc. had worked for Publisher’s Paper Company at Oregon City, OR. Publisher’s had a major problem with pollution of the Willamette River caused by their discharge of spent pulping liquor. Austin had the idea of concentrating the liquor by freezing the water in the liquor and separating the ice. The resulting concentrated liquor would be easier to reuse.

Freezing tests were needed. Austin somehow secured a sizable plate freezer, which he located in the boiler/coffee room.

My workload must have been light at the time because I was to help with the operation, testing, and analysis of the freezing process. It was immediately obvious that freezing pulp liquor is not as easy as making ice cream- – – which was the limit of my freezing experience. In addition, the freezer was difficult to clean without making a mess of our social center. It was also obvious that pulp liquor, in combination with the considerable output of Austin’s pipe, resulted in a distinct fragrance.

Even though the freezing effort did not solve the liquor problem, the resulting fragrance did get the coffee break time back down to the allotted 15 minutes.

Industrial Processes Group

The industrial processes group grew out of the wastewater group. This group focused on environmental projects for industrial clients. It became the 30’s discipline. I headed this group until 1978 when Dot and I moved to Denver where water and wastewater projects had been the beginning and continued to be the core market.

The people, projects, and clients were the joy of my career. My interest in industrial waste originated with the guidance and assistance of Professor Fred Merryfield.

You Only had One Job?

I retired in 1987 after 30 years with only one firm. Oh ya! The Cornell, Howland, Hayes & Merryfield that hired me had metamorphosed into a different firm several times during those 30 years. How did this happen? Lack of control.

Most businesses don’t survive 30 years (much less 60+).

Retired? – – – How do you Keep Busy?

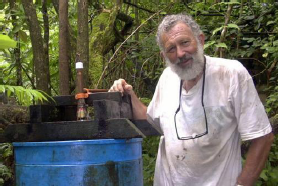

I found a hands-on water project on Rarotonga, Cook Islands. It is on a Takitumu Reserve for the endangered Kakerori, the Rarotongan Flycatcher (Google it). The project encompasses a water intake, pump station, surge tank with automatic float valve, pressure pipes, and point-of-use fixtures at the visitors centre.

The intake is on a very small tropical stream (no permits required). A ram pump of New Zealand manufacture is used, with great ingenuity, to avoid the need for electricity and instrumentation. The entire flow from the intake, 240,000 mL/hr, is required to operate the ram pump and lift 20,000 mL/hr to the 3,000,000-mL reservoir above the visitors centre. A majority of the piping used is corrosion-resistant PVC in sizes from 20 mm up to 50 mm. The point-of-use fixtures include an ambient-temperature shower, one crapper (second unit in planning stages), a hand sink, and a general-use stainless sink.

This work only required three onsite visits of 3 weeks’ duration spread over 4 years.

The project was completed on time and under budget- – – -or close, I think. [Happy client, Dr. Ed Saul to left.]

No help requested.

Postscript

It is wonderful to have a somewhat captive audience of people who have heard of CH2M HILL and have an idea of what it does. How do you answer in one sound bit: “Who did you work for?” “What does CHtooemel do?”