Prepared by: Mark Boedigheimer, with contributions from: Steve Gelman, Earl Hadfield, Larry Well, Cliff Thompson, Bob Chapman, Tim Maloney, and others. January, 2016.

As one looks into the historic records of CH2M, and remarkably as far back as preserved messages between the founding fathers, the building blocks of a laboratory are found. In the spring of 1946, Jim Howland, while stationed on the island of Saipan (World War II), created a hand-sketched floor plan for a future engineering office building. In that floor plan, Jim included space for a laboratory, evidence that having a laboratory was important to the soon-to-be founders of CH2M. However, with business startup on the second floor of the Albright & Raw building in Corvallis, it is unlikely the first office location included a laboratory.

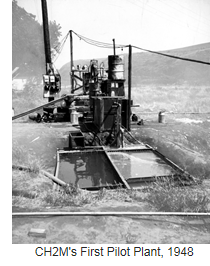

From the written record, we know that “making ends meet” was a key issue for this ambitious group of men. Interestingly, from the very earliest project records, we do know that strength of materials testing and treatability testing were being performed in those formative years. We have photo evidence that in 1948 Jim Howland performed treatability testing for the design of a wastewater treatment system for the City of Pendleton, Oregon. Given the inquisitive minds of the founders and first partners, we highly suspect tinkering and proof of concept were happening at the home workshops of Burke Hayes and Archie Rice, in particular.

From the Beginning and Decade of 1950s

The City of Pendleton project is but one example of what was truly a pent-up demand for post-War infrastructure development. This was, without a doubt, a time of much opportunity for the founders and partners. On a parallel course of growth was Clair A. Hill and Associates. Although the early records are less clear on the Hill side of CH2M HILL, by the mid-1950s, we find Harlan Moyer and Joe Patten at Clair A. Hill and Associates crossing paths and collaborating with the likes of CH2M’s Archie Rice and Ralph Roderick.

The late 1950s and early 1960s brought the workings of both firms in ever-closer contact. At both companies, prosperity was clearly found on projects dealing with water resources, water treatment and distribution, flood control and irrigation, municipal wastewater treatment, roads and airports, to mention a few. This work was a birth place for creativity and much innovation – something for which both CH2M and Clair A. Hill and Associates were well suited.

The early 1960s saw yet another infusion of talent with the addition of partners such as Earl Reynolds, Bob Adams, Sid Lasswell, and Fred Harem, to mention several. It is at this time that we see the first physical presence of laboratories at what will soon become a merger between CH2M and Clair A. Hill and Associates.

The 1960s

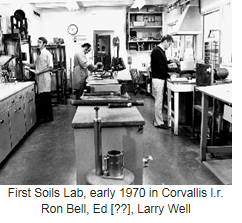

In the early 1960 era, Larry Well can be credited with the startup of a formal CH2M Geotechnical Testing Laboratory in a converted carport at the Corvallis office. Shortly thereafter, by conversion of yet more of the Corvallis office carport and use of open space in a nearby boiler room, Larry can also to be credited with startup of a CH2M Water Laboratory Program. From the recollection of many “old timers,” it appears Larry may have been CH2M’s first professional scientist.

Volumes can be written about Larry’s creativity and resourcefulness. Suffice to say here, Larry is clearly the patriarch of an official laboratory program at CH2M. Water Laboratory activities at that time supported projects with the wastewater characterization and development of design criteria for primary, secondary, and eventually tertiary treatment of municipal wastewater. The Geotechnical Laboratory provided strength of materials testing and provided data for use in the design basis on a wide variety of civil and structural engineering projects, many related to infrastructure design on water systems, wastewater systems, and transportation systems.

From a laboratory history point of view, the decade of 1960 was truly a formative period both at CH2M and at companies that, in time, will merge with CH2M. On the west coast of the United States, CH2M was literally writing the book on municipal wastewater treatment and design. As part of this, we see laboratory facilities under continued development at both CH2M and Clair A. Hill and Associates. On the east side of the U.S., a similar development was occurring at firms that would eventually become part of CH2M HILL. Black, Crow & Eidsness (BC&E), which opened in the 1940s as Black Laboratory in Gainesville, FL, evolved over the course of time into an engineering company. On another path, a laboratory founded in Montgomery, AL, in 1971 by Cliff Thompson, known as Thompson and Tuggle, also emerged and soon became part of BC&E. As we’ll soon see, in the early 1970s, the independent pathways of these “engineering” project support laboratories will soon cross.

The 1970s

When Congress passed the Clean Water Act, the Safe Drinking Water Act, the Clean Air Act, the Endangered Species Act, and similar laws in the early 1970s, the firm’s core engineering businesses truly blossomed into large engineering design disciplines; and several new business lines were added. While the core business grew at a double-digit pace, the Industrial Processes and Applied Sciences disciplines were born. The early 1970s was a time of unprecedented opportunity for engineering firms. This was a period of time where engineering and science were demanding creativity and excellence. Correspondingly, the pace of growth and infusion of brain power at CH2M was remarkable. On the municipal water and wastewater side of CH2M, the laboratory began support to a whole new line of engineers lead by the likes of Sid Lasswell, Gene Suhr, and Tom Gibbs. Don Evans, Don Marske, Bob Chapman, and many more were frequent users of the Corvallis Water Laboratory. On the Industrial Processes side, Bob Pailthorp led the intellect of Ralph Peterson, Jay Mackay, John Lee, Mike Harris, and others in the burgeoning industrial wastewater treatment business. Here again, the internal laboratories were a vital resource for the development of the technologies needed for the often difficult-to-treat industrial wastes that were being regulated for the first time.

The South Tahoe Public Utility District (PUD) tertiary treatment project that ultimately led to a merger of CH2M and Clair A. Hill and Associates in 1971 also brought together the Water Laboratories in Corvallis and Redding managed by Earl Hadfield and Ray Prettymen, respectively. Of significance to laboratory history, at this point in time, the Microfloc (first-of-a-kind multimedia filtration) process was undergoing development, pilot testing, and commercialization in Corvallis. Similarly, at Redding, the ARRP (first-of-a-kind ammonia removal and recovery system) process was developed, pilot tested, designed, and built. Both treatment technologies were used in the final design of the nationally accredited South Tahoe PUD tertiary treatment system. Although it was consistently true since Jim Howland had piloted primary biological treatment at the City of Pendleton back in the late 1940s, the contributions of the laboratory on the South Tahoe PUD project is yet again an example of how the firm’s internal laboratory resources and capabilities continued to make a difference in the work of the company.

The Milwaukee project represented a milestone in the time-line of the laboratory. CH2M HILL was tasked with setup and operation of a laboratory dedicated to wastewater characterization. Over the course of a year or so, tens of thousands of samples were processed. Although this project support laboratory was not directly owned by CH2M HILL, our Laboratory Program under the Management of Earl Hadfield was called upon to set up, manage, and staff laboratory operations.

To summarize the 1970s: The newly instated regulations on water and wastewater, along with the explosive growth it brought about inside of CH2M HILL, created a large body of project managers and engineers whose work then accelerated further development of Water Laboratories at both CH2M HILL and Clair A. Hill and Associates. At CH2M in Corvallis, as previously noted, water testing that started on a bench in the Geotechnical Laboratory by Larry Well grew into a stand-alone, 200-square-foot (ft2) Water Testing Laboratory. This new water laboratory was initially operated and then managed by CH2M HILL’s first professional chemist – Earl Hadfield. And, by the mid-1970s, Earl and two technicians (Mark Boedigheimer and Kelly Cook) were well on their way to establishing a long legacy of laboratory support to CH2M HILL projects. One step in that direction occurred late in the 1970s when the Corvallis Water Laboratory was expanded to 800 ft2 as part of the Corvallis office expansion. The laboratory expansion supported addition of more sophisticated instrumentation for the measurement of low-level (parts per billion [ppb]) metals by atomic absorption spectroscopy and the ability to quantify broad classes of organic contaminates by gas chromatography.

The 1980s

In early 1980, the Resource Conservation and Recovery Act (RCRA) took effect. This spurred a whole new set of analytical testing requirements. The engineering demands of RCRA, along with the full impact of the others Acts of Congress, which were now in full swing, created a near “perfect storm” of work for CH2M HILL’s laboratories. Revisions to the Safe Drinking Water Act (SDWA) and National Pollution Discharge Elimination System (NPDES) resulted in more stringent regulations, including trace levels of metals and a wide suite of organic compounds in water and wastewater and discharge compliance based on whole effluent aquatic toxicity (bioassay testing). This drove the growth of the original Corvallis and Redding laboratories and increased capabilities in Montgomery and Gainesville as well as the continuation of the laboratory in Kitchener. Three Bioassay Laboratories sprung up in Gainesville, Milwaukee, and Corvallis in response to new whole effluent toxicity and bio-monitoring requirements in the NPDES permits across the country. Similarly, with passage of the Comprehensive Environmental Response, Compensation and Liability Act (CERCLA – a.k.a., Superfund) by Congress in 1983, a newly formed Environmental Science Group built and operated two mobile laboratories – known as the Close Support Laboratory (CSL) Program. Our CSL Program was managed by Mark Boedigheimer. Over the course of CH2M HILL’s multiple contracts under The U.S. Environmental Protection Agency (USEPA) Superfund, the CSL Program performed onsite analytical support on more than 100 Superfund projects in more than two dozen U.S. states over a period of 10 years. We literally stopped counting the total number of samples analyzed at CSLs at around 100,000. By the mid-1980s, CH2M HILL owned and operated a collection of seven laboratories (or eight, depending on how one counts) that employed well over 200 analytical chemists and scientists.

To say the least, CH2M HILL’s work for the Federal Government under RCRA and CERCLA brought about significant changes to CH2M HILL’s internal laboratory program. The demand for high volume and routine analytics on hundreds of site investigations at hazardous waste sites across the nation dictated a restructuring of CH2M HILL laboratory resources. In 1983, Quality Analytical Laboratories (QAL) was formed and led by Cliff Thompson. QAL was established as a wholly owned subsidiary of CH2M HILL with a mission to provide high quality and high throughput analytical services. QAL included the chemistry laboratories located in Montgomery, Gainesville, and Redding. The Kitchener laboratory was sold due to regulatory climate and market differences in Canada. After an initial period of profitability, Bioassay laboratories in Milwaukee and Gainesville operated by the Applied Sciences Discipline were sold, leaving a single Bioassay Laboratory in Corvallis. Through all of the change, in 1985 the Corvallis Laboratory (now known as the Applied Science Laboratory [ASL]) was realigned to the Industrial Process (IP) Business Group. ASL was held in the IP Group with a mission to serve CH2M HILL’s core business customers often unique laboratory needs, to closely serve projects, facilitate technology development, and be a differentiator for CH2M HILL in the engineering market place. In 1987, Mark Boedigheimer became the manager of ASL.

The 1990s

Throughout the 1990s, growth in the company’s core water and wastewater businesses grew at a steady pace both on the municipal and industrial sides. On large Superfund contracts with the Federal Government, project work began to evolve from site investigations to remedial actions. This brought about a need for feasibility studies, much of which started with treatability bench testing and proof of concept tests at ASL. ASL was a test bed for innovative solutions to many of the nation’s most perplexing hazardous waste sites. First-of-a-kind solutions, such as air stripping, advanced oxidation, in situ bio-augmentation, ion-exchange, barrier walls, to mention just a few, were tried and proven at ASL by the likes of Jim Mavis, Bill Byers, Tom Higgins, and a long list of soon-to-be Technology Fellows.

Unfortunately, after initial periods of success in the commercial testing business, QAL laboratory’s profitability was negatively impacted by the entry of large commercial laboratory competitors and a lack of unified support from within the company. In 1993, QAL was sold. However, in the interest of retaining laboratory services that closely supported the unique needs of projects and to carry out strategic technical research and development, our then CEO, Ralph Peterson, made the command decision to retain the Corvallis laboratory – ASL. In effect, Ralph’s act helped firmly establish ASL as a strategic resource whose mission was to provide unique analytical needs to projects, be the platform for treatability testing and proof of concept work, and help business groups carry out technical initiatives relative to emerging opportunities. Harking back to the earliest communications among the founding fathers, it could be said that Ralph’s retention of ASL reaffirmed what Jim Howland had envisioned in 1946 when he included laboratory space in his conceptual floor plan for the first CH2M office.

In the mid-1990s, modifications to the Safe Drinking Water Act created a new focus on disinfection by-products in drinking water supplies and a whole new set of emerging contaminants. In 1996, the USEPA issued an Information Collection Rule (ICR) to all large Water Suppliers. The ICR included a need for Water Utilities to conduct treatability and operational control studies to control disinfection by-products. In concert with the Water Business Group, between 1996 and 1999, ASL performed hundreds of ICR treatability studies for CH2M HILL’s core water business customers. This business initiative was done largely by none other than Bill Bellamy, Paul Swaim, Tony Myers, Russell Ford, and many other of CH2M HILL’s giants in the U.S. water treatment business. By the end of the decade, treatability testing by itself was a multi-million dollar part of ASL’s business. To handle the growing surge of treatability work, in 1996 Tim Maloney became ASL’s manager of Treatability Services.

At this juncture, ASL was now a group of more than 50 scientists. The Laboratory itself had literally taken over the entire lower level of the Corvallis office complex with offsite storage of supplies and equipment. The degree of sophistication in the analytics needed to support CH2M HILL’s Water and Wastewater business had grown to the level of parts per billion (ppb) detection limits for the full suite of priority pollutants and conventional water quality parameters. Whereas the 1960s and 1970s could be characterized as decades of parts per million (ppm) measurements, the 1980s and now the 1990s were the decades of ppb measurements. ASL’s tool set, analytical capabilities and staff competency, was now equal to that of a mid-sized commercial Environmental Testing Laboratory.

By the end of the decade, laboratory accreditation had become a fact of life at ASL. Virtually all of CH2M HILL’s Federal- and State-led environmental projects required laboratory accreditations. In addition, a growing number of private sector customers also required some form of third-party laboratory accreditation. At the end of the decade, ASL had achieved laboratory accreditation under the National Environmental Laboratory Accreditation Conference (NELAC), Air Force Center for Environmental Excellence (AFCEE), U.S. Army Corps of Engineers (USCOE), International Organization for Standardization 17025 (ISO-17025), and in 14 different State Regulatory Programs and 3 private clients. In 1999 alone, ASL underwent eight separate independent quality audits. At one point, ASL‘s Quality Assurance Officer determined that one in five samples analyzed was for the purpose of satisfying accreditation requirements!

The New Millennium – 2000

By most measures, it could be said that, at the start of the new millennium, ASL was no longer just a small project support laboratory. When measured against other engineering companies with laboratory capabilities, ASL was easily at the head of the class. ASL had not only amassed a unique suite of cutting-edge water and wastewater treatment technology testing capabilities, along the way we had also reached the status of a full-service environmental testing laboratory. In year 2001, ASL’s annual business volume was pushing $5 million. More importantly, in the course of a year, ASL was touching over 350 CH2M HILL projects in one manner or another. Our laboratory services profile now included: Treatability/Proof of Concept Testing; Toxicity and Bio-monitoring; Air Toxics/Indoor Air/Vapor Intrusion Testing; Laboratory Program Development Consulting (i.e., laboratory design services, laboratory program development, quality audits/training, laboratory information system development, etc.); routine organics/inorganics/general testing; and more. Suffice to say – ASL had passed from adolescence into adulthood.

At the start of the new millennium, CH2M HILL had in its ASL a laboratory that could create revenue from a growing volume of routine analytical work on large federal hazardous waste site remediation projects. At this juncture, a decision was reached to operate ASL as a profit center by having ASL perform a larger volume (up to 30 percent) of routine analytics. The logic was that margin made on routine analytical work would help offset the ever-increasing cost of the analytical technology and fixed costs requisite to measurement of trace level (i.e., ppb and parts per trillion [ppt]) contaminants on mission-critical work, such as treatability testing and special analytical support. As hoped, throughout the decade, ASL was successful in not only operating with a nice profit margin but continued to capitalize the laboratory with mission critical tools and invest in emerging technologies.

In 2004 ASL, in concert with CH2M HILL’s Industrial Water group, responded to emerging opportunities in the Oil Sands region of Alberta, Canada. In situ steam assisted extraction of bitumen (heavy oil) from oil sands creates 2.3 barrels of contaminated process water for each barrel of heavy oil produced. Process water from in situ operations is treated and reused as boiler-feed water supply. In 2004, water treatment and analytical chemistry were highly sought-after fields of expertise for which CH2M HILL was uniquely qualified. As part of the water treatment projects at Petro-Canada, Suncor Energy, Conoco Phillips, Nexen Energy, and StatOil, ASL helped established laboratory programs and performed laboratory startups and laboratory operations training. For a period of 10 years, as many as 14 ASL staff operated the Water Quality and Bitumen Laboratories for Suncor Energy at their MacKay River SAGD facility. During this assignment, ASL staff developed many analytical methods for process water and boiler-feed water quality that are in use today across the Oil Sands region of Alberta.

In 2008, with the lease at the Western Boulevard location nearing expiration and ASL having literally outgrown its ability to operate in the lower level of the Corvallis Office building, a request was made to the CH2M HILL Senior Executives by Steve Gelman, President of the Industrial Water Business Group, and Mark Boedigheimer, Director of ASL, to relocate and expand ASL. With management approval in early 2009, design of a new laboratory was undertaken by the CH2M HILL Industrial and Advanced Technology design group. Laboratory construction was initiated in early 2010 with completion in the fall of 2010. ASL was relocated from its Walnut Boulevard location to the new 20,000-ft2 laboratory facility located on the Hewlett-Packard Business Park also in Corvallis, Oregon.

2010 and Beyond

Shortly after relocation of ASL to its new facility in late 2010, the Environmental Sciences Business Group, as a means to meet its federal project small business set-aside commitments, found a need to outsource laboratory work being performed at ASL. As can be imagined, the associated loss of revenue had a detrimental impact on ASL’s operations. Nonetheless, from 2010 through 2013, ASL continued to deliver on its primary mission of providing strategic services to CH2M HILL’s core water and wastewater businesses, albeit at a lower profit margin.

As of this writing, we are working with CH2M management to recommit to the ASL mission and help increase internal awareness on the value of ASL to CH2M’s overall value proposition to its clients. This is no small challenge, given the pace of change within CH2M and as staff with decades of longevity retire. But we have put in place a Steering Team to better connect ASL with our businesses and form internal partnerships to help guide ASL’s investment in emerging technology and the company’s marketing initiatives, and to build capabilities that are consistent with CH2M businesses growth and delivery plans.

Rest assured, when ASL’s mission and services are viewed in the context of CH2M’s aspirations, goals, and strategy, its strategic value to the enterprises does come into plain view. This was apparent to the founding fathers in 1946, and to the extensive list of engineers, scientists, and leaders who have supported the laboratory for more than four decades.